Process & Manufacturing Technology

Process

In your organization, there are constant challenges to streamline post-approval changes to meet market demand and prevent drug shortages. Critical to a streamlined process is robust process change management with targeted assessments giving you the desired outcome to reduce deviations, lower cost of quality, and enhance your regulatory strategy.

Successfully following our model your total lifecycle costs will be reduced, making your organization more competitive in your respective market place. This increases your chance of success when you want to:

- Introduce change into your process for scale-up

- Upgrade unit operation equipment

- Propose a process improvement

- Introduce operational excellence and reliability programs

CAI has diverse process unit operation expertise spanning multiple product platforms. We develop control strategies that permit reduced process validation timelines and reduce total product lifecycle costs. Working together with your team to formally characterize and reduce process variability, we can strengthen your case for abbreviated and accelerated agency timelines.

Technology Transfer

Technology transfers are critical to meet both new product supply to the market as well as to redistribute internal capacity for optimal overall equipment effectiveness (OEE) within your organization, but they don’t have to be so complex.

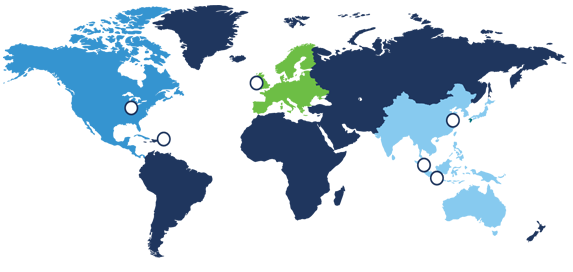

A typical technology transfer spans across multiple sites around the globe including many stakeholders from cross-functional teams. Your key to success in transferring your product and process knowledge centers around a robust platform and understanding of the sending unit process and basis for comparability.

We have a global team of multi-disciplined technical transfer experts who can reduce total product transfer costs and accelerate project timelines by providing regional market expertise for both the Sending Unit and Receiving Unit under a singular communication and knowledge management framework. By partnering with CAI, we can align your stakeholders and set your program vision. We can then lead your team through the process while reducing variability and assuring a successful technology transfer.

New Technologies

There is a dependent relationship between clinical trial design, phase and scale-dependent product processes, and the reimbursement scheme for a desired indication or outcome. A change in one significantly impacts the other and often results in a bridging study. For regenerative medicines, it is more critical to invest in front-end product process knowledge prior to Phase 2 with cross-functional team representation by Commercial, Clinical, and Manufacturing.

Robust product process knowledge management will be key to transitioning the Phase 2/3 divide: to scale the process without introducing sufficient change to require additional bridging studies or impact reimbursement strategy.

The training and administration practices of the clinician are critical to the successful therapy delivery. It is a complex supply chain that both starts and finishes outside of the typical cGMP manufacturing paradigm and requires enhanced and specialized training to be able to administer treatment safely.

CAI has a unique combination of expertise both in emerging product platforms and contract development and manufacturing management, which enables us to accelerate our sponsor and virtual company clients’ time to market for new product commercialization.